8620 Alloy Steel

8620 alloy is a popular choice when manufacturing high-stress components such as gears and camshafts. Its great hardenability, strength, and toughness are attributed to the addition of nickel, chromium, and molybdenum as elements during its processing. Additionally, this particular material is also highly weldable and machineable.

Friend Metals Distributor is proud to provide customers with the highest quality 8620 alloy products. Our selection of products includes forgings and bars that come in a variety of sizes and shapes, allowing us to meet each customer’s individual needs.

Call Us at 714-632-0140 or Toll-Free at 800-854-6777.

8620 Forging

Friend Metals offers a vast selection of 8620 forgings crafted through open-die, closed-die, and ring rolling methods. The advantages of this remarkable steel are plentiful; it is known for its mechanical strength, toughness, and ability to be hardened. Therefore it is an excellent material for forging applications.

Forging is a process that shapes materials by pressing them between two dies. An example of this type of forging is the production of large, irregularly-shaped parts like shafts and discs with an ‘opened-die’ approach. However, more complex geometries such as gears and crankshafts can be made using the ‘closed-die’ method which compresses material inside dies that fully encompass it. Finally, ring rolling produces seamless rings boasting uniform wall thicknesses – excellent for use in bearings and other vital applications.

When it comes to the fabrication of robust, high-stress components like gears, axles and shafts, 8620 alloys are often the go-to choice. Heat treating this material further can significantly boost its mechanical properties such as strength, hardness, and toughness. This is done by processes like normalizing, annealing or quenching and tempering.

Our team of professionals will help in selecting the right forging operation and heat treatment for the required mechanical properties that fit their application needs.

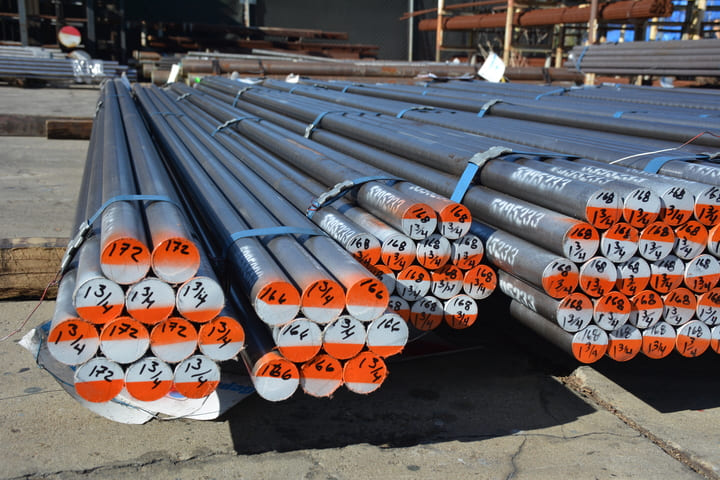

8620 Bar

At Friend Metals Co, we specialize in producing quality-assured 8620 low-alloy steel bars. This particular grade of steel is highly valued for its hardenability, strength and toughness as well as machinability due to its elements including nickel, chromium and molybdenum. Our ranges of bars are produced using a selection of hot and cold rolling processes to suit our customers’ individual requirements.

8620 steel bar is a popular choice for the construction of parts which require subjection to high amounts of stress, like cogs, camshafts and axles. These bars come in all shapes and sizes such as round, rectangular or hexagonal to cater to individual demands. In addition to that, this material can be further tempered so as to increase its mechanical features like hardiness, power and endurance.

8620 alloy bars typically undergo a few different types of treatments to obtain desired characteristics, such as quenching and tempering, annealing, and normalizing. Quenching and tempering consists of heating the bars up to a certain temperature followed by rapid cooling, which results in increased strength, hardness, and toughness. Annealing requires that the material be heated to a particular temperature and then allowed to cool slowly so that machinability is improved while internal stress is reduced. Lastly, with normalizing the alloy needs to be warmed up until it reaches a given temperature before allowing it to cool down in still air; this produces more toughness and strength.

AMS 6274

8620 bars, which fulfill the requirements of AMS 6274, are widely utilized in the construction of various heavy-duty parts and components. This type of steel is a low-alloy metal that consists of nickel, chromium, and molybdenum as its alloying elements. It stands out for its remarkable toughness, strength, hardenability and machinability characteristics.

AMS 6274 is a set of regulations that deals with hot-wrought, normalized or annealed bars made from 8620 alloy. These metal components are often used for creating aircraft and aerospace parts and have a range of sizes and shapes including round, square and hexagonal – to suit many different needs. Furthermore, it is possible to apply additional heat treatments which can boost their mechanical properties like strength, resilience and hardness.

When working with AMS 6274 alloy steel 8620 bars, a variety of procedures can be done in order to improve its properties. These include quenching and tempering, annealing, and normalizing. Quenching and tempering require the material to be heated at one temperature before cooling it down rapidly (quenching) and then reheating at another lower temperature (tempering). This method will result in a bar with high strength, hardness, and toughness. Alternatively, annealing can yield improved machinability along with reduced internal stresses by heating it at a certain temperature then letting it cool slowly. Lastly, normalizing requires heating the material to a particular degree before allowing it to air-cool; this will bring out greater strength as well as enhanced toughness.

Friend Metals specializes in 8620 alloy bars that comply with the AMS 6274 specification. Reach out today to learn more about our 8620 bars and what we offer

8620 Alloy Chemical Composition

The chemical composition of 8620 alloy typically includes the following elements:

- Carbon (C): 0.18-0.23%

- Manganese (Mn): 0.70-0.90%

- Silicon (Si): 0.15-0.35%

- Nickel (Ni): 0.40-0.70%

- Chromium (Cr): 0.40-0.60%

- Molybdenum (Mo): 0.15-0.25%

8620 Alloy is renowned for its unique qualities, enabling it to be used in a variety of applications. Among these are its outstanding hardenability, strength, toughness and machinability; all ideal attributes for components under high stress such as gears, camshafts and axles. Hence this metal has become increasingly popular in defense and aerospace industries.

8620 Alloy Mechanical Properties

8620 alloy has a range of mechanical properties that depend on both its heat treatment process and application. Generally, it is recognized for its:

- Tensile strength: 105-135 ksi (724-931 MPa)

- Yield strength: 60-100 ksi (414-690 MPa)

- Elongation: 15-25%

- Reduction of area: 40-60%

- Hardness (in the quenched and tempered condition): 20-25 HRC

- Impact strength (in the normalized condition): 35-50 ft-lb (47-68 J)

Heat treatments such as quenching and tempering, annealing, and normalizing can significantly enhance the characteristics of 8620 alloy . Quenching and tempering can up its hardness and strength, while annealing makes it easier to machine and reduce internal strain. In summary, each of the processes provides beneficial properties for the alloy.

When selecting 8620 Alloy, its mechanical properties are subject to varying influences such as the production technique employed, its size and shape, and the heat treatment procedure applied. Contact us find the correct 8620 Alloy and corresponding heat treatment process for your application.